内容目录

Starting a conversation about the quality assurance processes in stainless steel ring manufacturing isn’t just technical—it’s crucial for the reputation of businesses in this competitive industry. Whether you’re a newcomer or a seasoned player in the B2B realm, understanding these processes can be a game-changer.

Ensuring the quality of stainless steel rings for major retailers involves a combination of rigorous testing, adherence to industry standards, and continuous improvement practices. Let’s dive into what makes the wheels turn behind the scenes in this sector.

Raw Material Selection

The journey of a high-quality stainless steel ring begins with the selection of top-grade materials. Manufacturers like Burke Forging & Heat Treating, Inc., and All Metal Sales, Inc., emphasize the importance of using premium stainless steel that resists corrosion and maintains its aesthetic appeal.

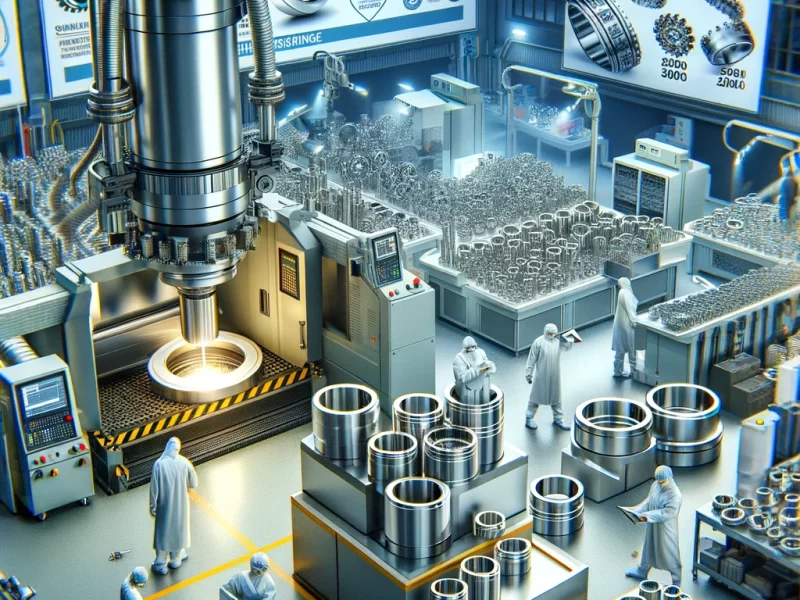

Precision in Manufacturing

Precision is key in the manufacturing process. Facilities equipped with advanced machinery and technology, such as laser cutting and computerized numerical control (CNC) machines, ensure that each ring meets exact specifications with minimal deviation. This precision not only caters to the aesthetic and functional requirements but also ensures that the rings can withstand everyday wear and tear without losing their integrity.

Rigorous Quality Control Testing

Quality control is where the rubber meets the road. Each batch of rings undergoes several tests to check for durability, resistance to corrosion, and overall strength. Techniques like X-ray fluorescence (XRF) analyzers are used to verify the composition of the metal, ensuring that only the intended materials are used and that they meet the specific standards required by clients like major retailers.

Customization and Client Feedback

Customization is a significant aspect of production, especially when dealing with diverse clients like Walmart or Macy’s. Manufacturers often provide bespoke solutions, adapting designs based on retailer specifications and feedback. This iterative process helps in refining the product and aligning it more closely with market demands and consumer preferences

.

Ethical Sourcing and Sustainability

In today’s market, sustainability also plays a crucial role in quality assurance. Companies are increasingly adopting ethical sourcing practices and using recycled materials to not only appeal to environmentally conscious consumers but also to enhance the overall quality and lifecycle of their products.

Continuous Improvement

Lastly, the principle of continuous improvement drives manufacturers to constantly upgrade their processes, learn from feedback, and innovate in their techniques. This proactive approach ensures that they remain competitive and continue to meet the high standards expected by major retailers.

Understanding these facets of manufacturing not only helps in selecting a reliable supplier but also in appreciating the intricacies involved in producing a seemingly simple product like a stainless steel ring.

Compliance with International Standards

Quality assurance doesn’t stop at the factory gates. Adhering to international standards is a critical aspect that stainless steel ring manufacturers must manage. Standards such as ISO 9001 for quality management systems provide a framework that ensures consistency in product quality. These standards are not just about the final product but encompass the entire manufacturing process from procurement, and production, to post-production services.

Supplier Audits and Certification

To further bolster trust and reliability, major manufacturers undergo regular supplier audits. These audits are conducted by independent third parties and can be a rigorous check of everything from the sourcing of materials to the working conditions in factories. Certifications resulting from these audits, like those from the Responsible Jewellery Council, serve as a testament to a manufacturer’s commitment to quality and ethical practices.

Advanced Technology in Testing and Monitoring

The role of technology in quality assurance is becoming increasingly sophisticated. Modern manufacturers employ various high-tech methods to test and monitor the quality of their rings. For instance, 3D scanning and imaging provide precise measurements and detect microscopic defects that could affect durability or appearance. This technology ensures that every ring matches the design specifications to a tee and meets the aesthetic requirements of high-end retailers.

Feedback Integration and Adaptation

Feedback from retailers and end-consumers is invaluable. Successful manufacturers establish robust mechanisms to gather, analyze, and integrate feedback into their manufacturing process. This loop of continuous feedback and improvement helps manufacturers to stay ahead of consumer trends and adjust their processes and products accordingly. It’s not just about correcting flaws; it’s about enhancing features and innovating new designs that meet evolving customer preferences.

Final Product Inspection and Packaging

Before the stainless steel rings reach the retailer, they undergo a final inspection to ensure that each piece meets the stringent quality criteria. The packaging process also plays a crucial role in maintaining the quality during transportation. Manufacturers use secure, damage-proof packaging to ensure that products arrive in pristine condition, thus avoiding any potential customer dissatisfaction upon delivery.

Training and Development for Quality Assurance

Behind every quality assurance process are skilled individuals. Investing in training and development ensures that the workforce is knowledgeable about the latest industry standards and capable of maintaining high-quality production. This not only helps in reducing human error but also fosters a culture of quality and excellence within the organization.

By meticulously managing every aspect of the production process and maintaining stringent quality controls, manufacturers of stainless steel rings ensure that their products consistently satisfy the expectations of major retailers. This comprehensive approach to quality assurance not only secures business relationships but also builds the brand’s reputation in the global market.

Leveraging Technology for Enhanced Precision and Efficiency

In the realm of stainless steel ring manufacturing, the integration of cutting-edge technology not only enhances precision but also boosts production efficiency. Automation and robotics are increasingly being adopted to handle repetitive tasks, which minimizes human error and increases the speed of production. For instance, automated polishing machines ensure that each ring achieves the perfect finish without variations.

Embracing Digital Design and Prototyping

Digital design tools, such as Computer-Aided Design (CAD) software, play a pivotal role in the design phase of stainless steel rings. These tools allow for intricate designs to be precisely planned and visualized before production begins, ensuring that the final product aligns perfectly with the design specifications. Additionally, rapid prototyping techniques like 3D printing enable manufacturers to create prototypes quickly and cost-effectively, allowing for faster iteration and refinement based on retailer feedback.

Ensuring Traceability and Transparency

Traceability in the supply chain is another crucial aspect that high-quality manufacturers prioritize. By implementing systems that track the journey of a product from raw material to final product, manufacturers can provide assurances of quality and ethical sourcing to retailers. This transparency not only builds trust but also helps in managing recalls efficiently if any issues arise post-production.

Navigating Global Standards and Compliance

Manufacturers must navigate a complex landscape of global standards and regulations, which vary by country and region. Ensuring compliance with these regulations, such as those about nickel release (important for hypoallergenic jewelry), is essential for accessing international markets. Compliance helps mitigate risks and reinforces the manufacturer’s commitment to safety and quality.

Building Long-Term Relationships Through Quality Assurance

Quality isn’t just about the product; it’s about building relationships. Manufacturers who consistently deliver high-quality products build long-term partnerships with major retailers. These relationships are based on trust and reliability, which are reinforced through consistent product quality and responsive customer service. By understanding and aligning with the business models and expectations of their clients, manufacturers can ensure a stable and profitable business relationship.

Conclusion

The assurance of quality in the manufacturing of stainless steel rings is a multifaceted endeavor that involves advanced technologies, stringent quality control measures, and a deep understanding of both market needs and regulatory requirements. By adhering to these practices, manufacturers not only meet but often exceed the expectations of major retailers, ensuring their place in a competitive market.

Innovating Beyond Standards: The Future of Stainless Steel Ring Manufacturing

As we look to the future of stainless steel ring manufacturing, it’s clear that innovation will continue to drive the industry forward. Emerging technologies not only promise to enhance the precision and efficiency of manufacturing processes but also to introduce new materials and design methodologies that could redefine the market.

The Role of Smart Manufacturing

Smart manufacturing technologies, integrating Internet of Things (IoT) sensors and big data analytics, are set to revolutionize the production lines of stainless steel rings. These technologies enable real-time monitoring and adjustments during the manufacturing process, ensuring optimal performance and reducing waste. Predictive maintenance of machinery can also minimize downtime, ensuring a constant flow of production to meet retailer demands.

Sustainable Practices and Material Innovations

Sustainability continues to be a significant focus within the industry. Manufacturers are exploring more eco-friendly production methods and materials, including the use of recycled stainless steel and alternative energy sources for manufacturing plants. Furthermore, advancements in material science may introduce new alloys or treatments that enhance the properties of stainless steel, such as increased corrosion resistance or enhanced aesthetic appeal.

Harnessing Artificial Intelligence for Design and Customization

Artificial Intelligence (AI) is beginning to play a role in the customization of jewelry. AI can help predict market trends and consumer preferences, allowing manufacturers to design rings that are more likely to appeal to target demographics. Additionally, AI-driven tools can offer personalized design services directly to consumers, allowing for greater individual expression while maintaining the efficiency of mass production.

The Importance of Consumer Engagement and Experience

In the digital age, consumer engagement goes beyond the product itself. Manufacturers are increasingly using digital platforms to engage with customers directly, offering virtual try-ons, online customization tools, and interactive design platforms. These tools not only enhance the customer experience but also build a stronger brand connection, which is crucial for customer retention and satisfaction.

Conclusion

The journey of ensuring quality in stainless steel ring manufacturing is an ongoing process that adapts to time, technology, and consumer expectations. By embracing technological advancements, committing to sustainability, and fostering strong relationships with retailers and consumers alike, manufacturers are set to thrive in an ever-evolving marketplace.